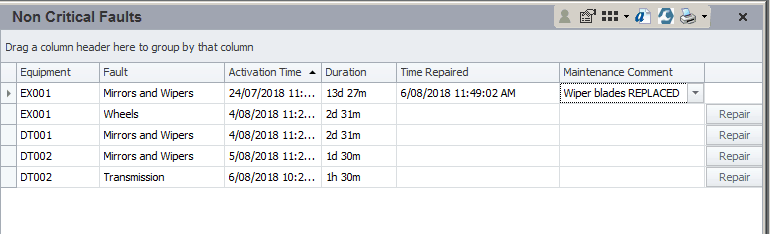

A key feature of Pitram is the Non-Critical Faults panel, which simplifies the process of collecting and managing data relating to maintenance issues. Non-Critical Faults are defined as minor maintenance/breakdown issues which do not impact the operational status of a piece of equipment.

The dedicated panel focuses on faults that do not have significant operational impact but are still required to be documented and reported on.

Figure 1. Non-Critical Faults panel in Pitram 4.10

Non-Critical faults can be captured via Pitram Voice system, which allows near real-time communication and data transfer between the operator and the control room. The live data is directly entered into Pitram by control room administrators, ensuring data accuracy. The machine operator calls the specific maintenance event through to the control room where it is entered into the Non-Critical Faults panel.

The timestamp (activation time) of the event is then recorded once the event is entered and the fault is considered ‘active’. The Control room and maintenance department can then monitor the active faults duration within Data Acquisition, giving operations staff and management full visibility of all current maintenance events.

Once the issue or fault has been repaired, the control room is notified by maintenance allowing the control room operator to resolve the fault in the Non-Critical Faults panel.

The recently released Pitram 4.10, the latest version of market leading fleet management and mine control solution Pitram, delivers a range of new features and functionality for users. On the back of consultation with our global client base and in an effort to continually evolve and enhance the Pitram solution, the functionality offered on the Non-Critical Faults panel has been enhanced.

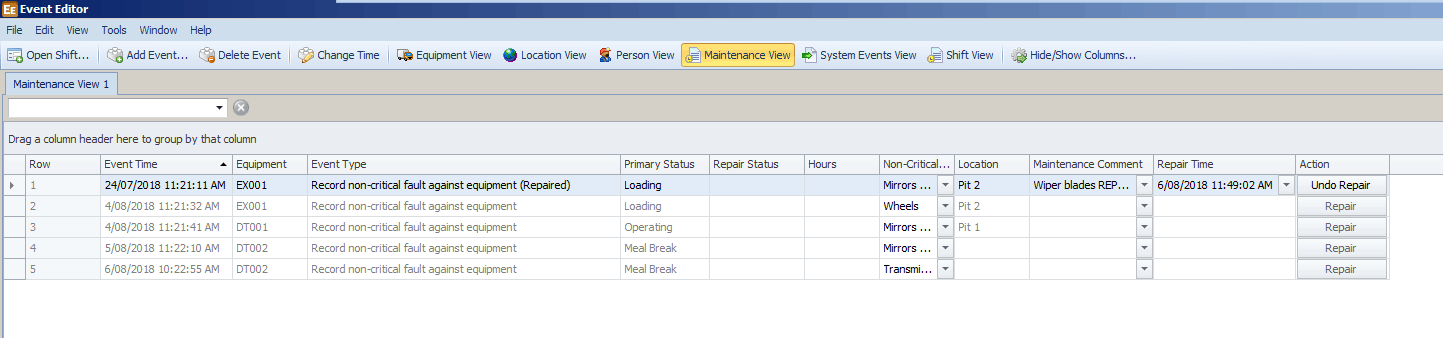

A new feature for Pitram 4.10 is the inclusion of a commenting section in Non-Critical Faults which gives the ability for maintenance team members to comment on and review current faults.

The Non-Critical Faults panel in Pitram 4.10 now gives the maintenance team the ability to add comments and review or edit events in Event Editor using the Maintenance View Section. This allows maintenance managers to provide insights into current faults, increasing visibility for Pitram users and management.

Figure 2. Maintenance view section in Pitram 4.10

Non-Critical faults can also be captured in Pitram Automated solution via Data Acquisition or incorporated into Mobile pre-start checklists. Reporting capability via Pitram Portal provides current and historical data for analysis, allowing managers to identify trends relating to faults and improve overall reliability on-site.

Pitram’s sophisticated yet intuitive functionality makes it ideal for all mining environments including underground and surface mine construction, development and production. It has been implemented at more underground sites than any competitor product, and is increasingly popular with sites using automated practices.

Click here to find out more about Pitram 4.10 fleet management solution.